Elevating Hygiene Standards: An Overview of Zinc Antimicrobial Additives in Thermoplastics

In the pursuit of heightened hygiene standards, the integration of antimicrobial solutions has become a focal point across various industries. A noteworthy contender in this arena is the utilization of zinc antimicrobial additives in thermoplastics, an innovative approach that enhances the materials' ability to resist microbial growth. This blog post provides a concise overview of the advantages and applications of zinc-infused thermoplastics, shedding light on their significance in the quest for cleaner, safer environments.

Zinc, a naturally occurring element with potent antimicrobial properties, serves as a powerful ally in the fight against bacteria, fungi, and other harmful microorganisms. When incorporated into thermoplastics, zinc ions act as a proactive defense mechanism on the material's surface, inhibiting the growth and spread of microbes.

The application of zinc antimicrobial additives is particularly impactful in environments where hygiene is paramount. From healthcare settings and food packaging to high-touch surfaces in public spaces, zinc-infused thermoplastics actively contribute to reducing the risk of microbial contamination. This not only addresses immediate hygiene concerns but also aligns with the growing demand for antimicrobial solutions in the wake of global health considerations.

An inherent advantage of zinc-infused thermoplastics lies in their ability to complement existing hygiene practices. While routine cleaning and disinfection remain essential, the antimicrobial properties of zinc additives provide an additional layer of protection, actively minimizing microbial growth between cleaning cycles. This is especially valuable in scenarios where continuous, rigorous cleaning may pose logistical challenges.

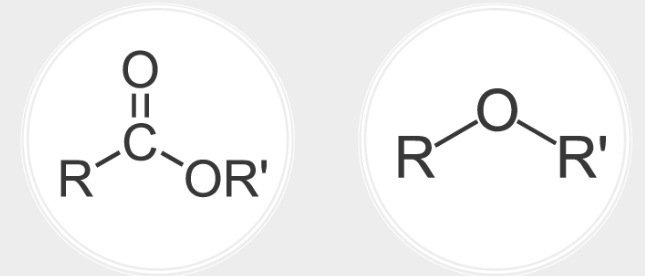

The versatility of zinc antimicrobial additives allows their integration into a diverse range of thermoplastic materials, including polyethylene, polypropylene, and polyvinyl chloride (PVC). This adaptability makes zinc-infused thermoplastics suitable for an array of applications, ranging from medical devices and packaging materials to consumer goods and building components.

The integration of zinc antimicrobial additives in thermoplastics represents a significant advancement in material science, elevating hygiene standards across industries. The innate properties of zinc, when harnessed in thermoplastics, create a proactive shield against microbial threats, contributing to the creation of cleaner, safer, and more resilient environments. As industries continue to prioritize health and safety, zinc-infused thermoplastics emerge as a key player in the collective effort to enhance hygiene practices and promote the well-being of individuals worldwide.