What is ABS Plastic?

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic polymer that finds wide-ranging applications in various industries. With its unique combination of properties, ABS has become a popular choice for numerous applications requiring durability, impact resistance, and versatility. In this blog, we will explore the features and benefits of ABS, shedding light on its key characteristics and highlighting its advantages in different industries.

Features of ABS:

1. Mechanical Strength: ABS exhibits excellent mechanical strength, making it a preferred material for applications that demand robustness and impact resistance. Its inherent toughness allows it to withstand external forces, making it suitable for protective housings, camera enclosures, and packaging materials.

2. Chemical Resistance: ABS demonstrates good resistance to a wide range of chemicals, including concentrated acids and dilute acids. It also exhibits excellent resistance to alkalis, contributing to its suitability in various industrial environments.

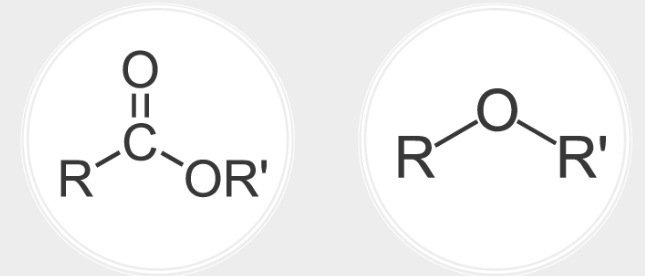

3. Heat Resistance: ABS offers high heat deflection temperature, thanks to the presence of acrylonitrile in its composition. This property allows ABS to maintain its structural integrity and dimensional stability even at elevated temperatures, making it suitable for applications requiring heat resistance.

4. Surface Finish: The styrene component in ABS provides the plastic with a shiny, impervious surface. This characteristic gives ABS a visually appealing appearance and enhances its aesthetic appeal, making it suitable for consumer products and automotive components.

Benefits of ABS:

1. Versatility: ABS is a versatile material that can be easily molded and shaped into complex forms. Its ability to be injection-molded or extruded into various shapes and sizes makes it a preferred choice in industries such as automotive, electronics, consumer goods, and construction.

2. Lightweight: ABS has a relatively low density, making it lightweight compared to many other thermoplastics. This characteristic is particularly beneficial in applications where weight reduction is desired, such as automotive components, aerospace parts, and portable devices.

3. Electrical Insulation: ABS possesses excellent electrical insulation properties, making it suitable for electrical and electronic applications. It can be used in the production of connectors, switches, and housing for electronic devices, ensuring reliable and safe electrical performance.

4. Recyclability: ABS is highly recyclable, which is advantageous from an environmental perspective. It can be melted and reprocessed multiple times without significant degradation of its properties, making it an environmentally friendly choice for sustainable manufacturing practices.

Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic polymer known for its exceptional mechanical strength, chemical resistance, heat resistance, and surface finish. Its features and benefits make it suitable for a wide range of applications across industries such as automotive, electronics, consumer goods, and construction. The versatility, lightweight nature, electrical insulation properties, and recyclability of ABS contribute to its widespread use and popularity in various manufacturing processes. As the demand for durable and versatile materials continues to rise, ABS remains a reliable choice for many industrial applications.