Understanding the Distinctive Characteristics of Copolymer and Homopolymer Polypropylene

In the realm of plastics and polymers, the distinction between copolymer and homopolymer propylene is fundamental, touching on the very structure and properties of these versatile materials. This article delves into the differences between these two types of polymers, shedding light on their unique characteristics, applications, and implications for the plastics industry.

At its core, the difference between a copolymer and a homopolymer lies in the composition of their molecular chains. A homopolymer propylene is a polymer that consists entirely of propylene monomers, meaning that every repeating unit within the polymer chain is identical. This uniformity grants homopolymer propylene a set of predictable properties, such as high strength, resistance to chemicals, and a high melting point. These characteristics make it an ideal choice for a wide range of applications, including packaging, textiles, and various components in the automotive and construction industries.

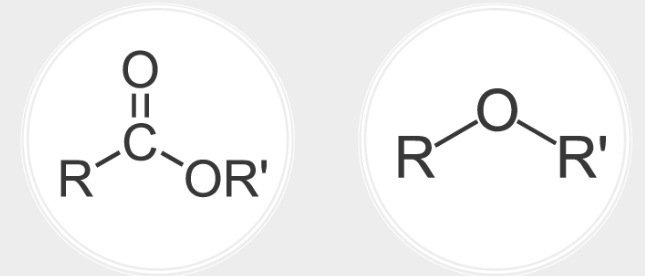

On the other hand, a copolymer propylene is formed when propylene monomers are polymerized together with one or more types of monomers. The incorporation of different monomers into the polymer chain introduces variability, which can significantly alter the material's properties. Copolymers can be designed to have improved impact resistance, flexibility, and transparency compared to homopolymers. They can also exhibit enhanced compatibility with other polymers and additives, opening up a broader range of applications such as in the manufacturing of clear storage containers, medical devices, and automotive parts.

The strategic selection between a homopolymer and a copolymer propylene hinges on the specific requirements of the application at hand. For instance, when high strength and chemical resistance are paramount, homopolymer propylene is the material of choice. Conversely, for applications demanding greater flexibility and impact resistance, copolymer propylene offers a tailored solution.

While both homopolymer and copolymer propylene are derivatives of the same fundamental monomer, their distinct compositions imbue them with different sets of properties and functionalities. This diversity underscores the versatility of propylene as a base material and highlights the ingenuity behind polymer engineering, allowing for tailored solutions that meet a wide array of technical and commercial demands.