News & Articles

The cutting-edge, glass-reinforced polymer enhances rigidity, aesthetics, and eco-friendliness of the surfboard fin

Syensqo’s Ixef® polyaryl amide (PARA) resin is used by Drake Plastics for molding the innovative Kohola FlowTech 1 Single Fin that enhances the flow control and efficient forward motion of surfboards to deliver longer and faster rides. The patented design of Kohola’s unique fins mimics the flippers of humpback whales. The efficiency of the injection molding process helped to achieve a manufacturing waste reduction of up to 30% compared to conventional fins produced with other techniques.

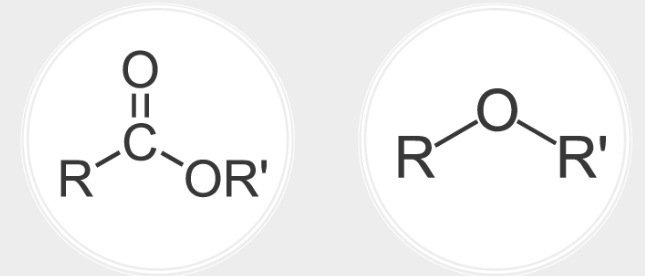

Understanding the Distinctive Characteristics of Copolymer and Homopolymer Polypropylene

In the realm of plastics and polymers, the distinction between copolymer and homopolymer propylene is fundamental, touching on the very structure and properties of these versatile materials. This article delves into the differences between these two types of polymers, shedding light on their unique characteristics, applications, and implications for the plastics industry.

Choosing the Best Resins for Ultrasonic Welding: A Comprehensive Guide

Ultrasonic welding is a widely adopted method for joining thermoplastic materials. This process uses high-frequency ultrasonic acoustic vibrations to create a solid-state weld, making it fast, efficient, and suitable for a wide range of applications. However, the success of ultrasonic welding largely depends on the selection of appropriate resin materials. This article delves into the considerations for choosing the best resins for ultrasonic welding, aiming to guide manufacturers in achieving strong, reliable welds.

Avoiding Cosmetic Defects in Injection Molded Parts: Strategies for Flawless Finishes

Injection molding is a cornerstone technique in manufacturing, widely used for producing parts with intricate shapes and high precision. While the process is renowned for its efficiency and versatility, manufacturers often face the challenge of cosmetic defects. These blemishes not only compromise the aesthetic appeal but can also affect the functionality of the final products. Understanding and addressing the root causes of these defects is crucial for maintaining high-quality standards. This article explores practical strategies to minimize cosmetic defects in injection molded parts.

The Science and Significance of PET Crystallization

Polyethylene terephthalate (PET) is a versatile polymer widely used in various applications, from packaging materials and textiles to engineering plastics. One of the critical aspects that determine the properties and suitability of PET for specific applications is its crystallization behavior. Crystallization affects the mechanical properties, thermal resistance, and clarity of PET products, making it a focal point of interest for both researchers and manufacturers. This article delves into the crystallization process of PET, exploring its mechanisms, influencing factors, and implications for material performance and application.

Understanding ISO 10993 Biocompatibility: Ensuring Safety in Medical Devices

In the realm of medical device development, ensuring the biocompatibility of materials is paramount for patient safety. ISO 10993, "Biological evaluation of medical devices," provides a comprehensive framework for evaluating the potential risks associated with the materials and processes used in medical device manufacturing. This blog post aims to elucidate the significance of ISO 10993 biocompatibility and its pivotal role in medical device approval processes.

Designing parts for injection molding

Designing parts for injection molding requires a detailed understanding of the process, materials, and design principles. This blog post aims to provide insights into creating efficient, manufacturable, and functional parts through injection molding, highlighting key considerations in the design phase.

Understanding REACH SVHC: A Comprehensive Overview

The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) is a European Union regulation adopted to protect human health and the environment from the risks posed by chemicals. A pivotal element within this regulation is the Substances of Very High Concern (SVHC) list. This list is not static; it's periodically updated to include chemicals that may have serious and often irreversible effects on human health and the environment.

The Versatility of PMMA in Outdoor Applications

In the dynamic realm of outdoor design, the selection of materials plays a pivotal role in achieving the perfect blend of visual allure, durability, and practicality. Poly(methyl methacrylate), more commonly known as PMMA, has swiftly become a formidable force in outdoor applications, boasting a unique set of characteristics that elevate the outdoor experience. Let's delve into the versatility of PMMA and uncover its manifold advantages in shaping and enhancing outdoor environments.

Unraveling the Distinctions: Amorphous vs. Crystalline Thermoplastics

In the vast realm of thermoplastics, two prominent categories stand out: amorphous and crystalline thermoplastics. Understanding the differences between these two types is crucial for designers, engineers, and manufacturers seeking to optimize material selection for various applications.